Businesses are constantly seeking methods to enhance production efficiency, reduce costs, and deliver high-quality products. Plastic injection molding has emerged as a powerful tool, offering a versatile and reliable solution for creating complex and precise plastic components. Whether you’re in the automotive, medical, consumer goods, or any other industry, understanding the benefits of plastic injection molding can significantly impact your business operations and growth. This blog explores six key advantages of utilizing plastic injection molding services.

Cost-Effectiveness in Large-Volume Production

Plastic injection molding is particularly advantageous for businesses that need to produce items in large volumes. Once the initial investment in design and mold creation is made, the cost per unit drops significantly as production scales up. This method ensures high production efficiency, with the capability to swiftly manufacture thousands or even millions of parts with minimal labor costs. Looking at more on injection molding from TechNH we can see that this process also allows for the use of alternative, less expensive materials such as recycled plastics, which can further reduce production costs. This makes plastic injection molding an ideal option for businesses looking to lower costs and increase profitability.

High Precision and Consistency

One of the standout benefits of plastic injection molding is its ability to produce highly precise and consistent parts. This process is particularly suited for industries where tight tolerances are crucial, such as the medical and aerospace sectors. The use of advanced machinery and well-designed molds ensures that each component is virtually identical, maintaining high standards of quality throughout the production run.

Furthermore, precision injection molding minimizes waste and reduces the need for additional machining or finishing processes, saving both time and resources. This level of accuracy and reliability makes plastic injection molding an excellent choice for businesses that demand dependable and uniform products.

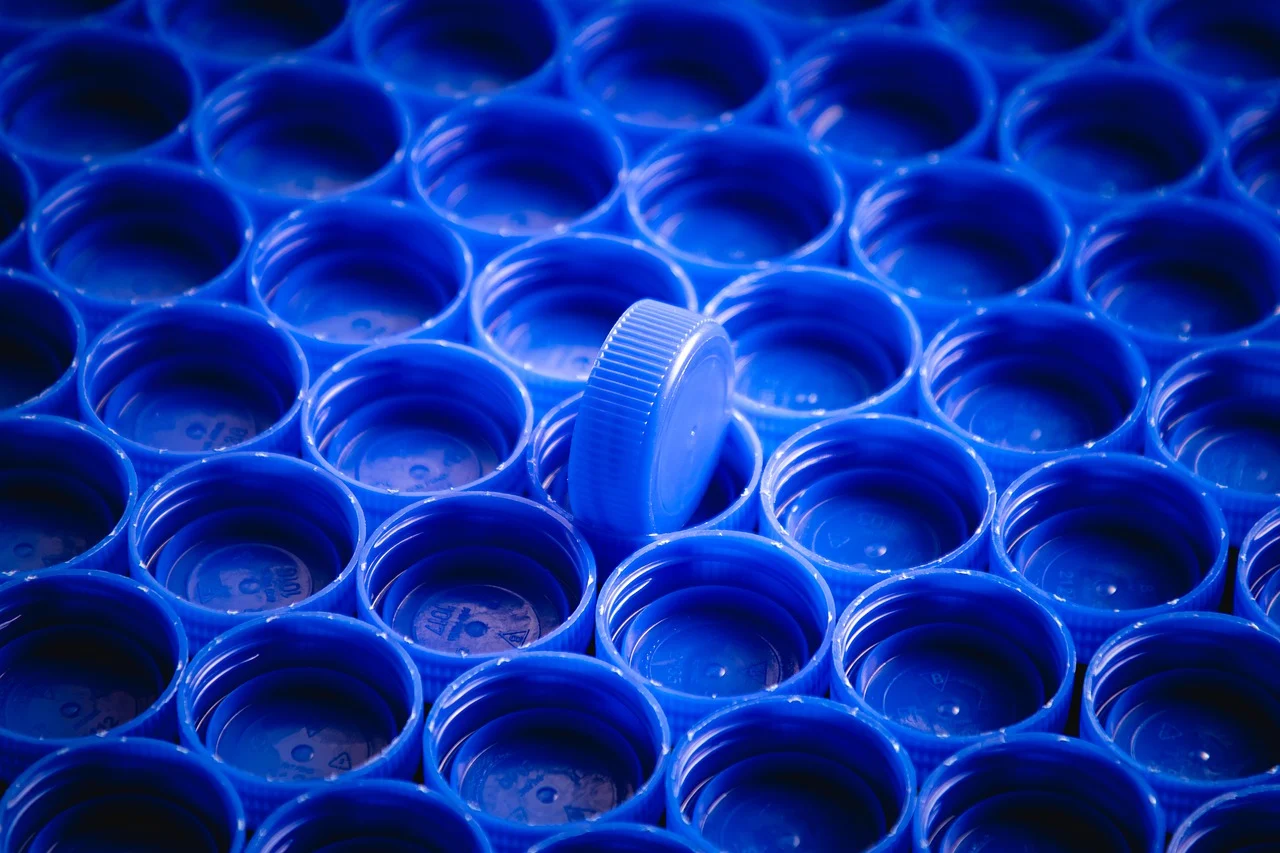

Flexibility in Material and Color Options

Plastic injection molding offers remarkable flexibility when it comes to selecting materials and colors, catering to diverse business needs. This process allows manufacturers to choose from a wide range of materials, including thermoplastics, thermosets, and elastomers, each providing unique properties suitable for different applications. This ease of material choice means that businesses can produce parts that meet specific requirements such as durability, elasticity, or resistance to heat and chemicals. Additionally, injection molding supports an extensive palette of colors, enabling the creation of aesthetic components that align with brand identity or product design specifications. Whether a business requires vibrant hues or subtle tones, plastic injection molding supports versatile options, making it an attractive choice for companies aiming to create innovative and customized products.

Efficient Production Speed and Output

Plastic injection molding is renowned for its exceptional production speed and output capabilities. Once the initial mold design and setup are completed, the actual molding process is remarkably rapid, allowing for the swift manufacture of a large volume of parts in a relatively short time frame. This efficiency is enhanced by the automation and precision of the machinery involved, ensuring that each cycle produces perfect replicas of the mold. Consequently, businesses benefit from reduced lead times and the ability to quickly respond to market demands or production schedules. Furthermore, high-speed production cuts down on labor costs and increases the overall throughput, making plastic injection molding an ideal solution for companies seeking to enhance their manufacturing efficiency and output.

Enhanced Strength through Additives

Plastic injection molding also offers the capability to incorporate additives that enhance the strength and durability of the finished products. These additives can be mixed into the base material during the molding process, resulting in parts that are specifically tailored to the performance requirements of various industries.

For instance, businesses can use reinforcing agents like glass fibers or mineral fillers to significantly increase the structural strength and rigidity of their components. This ability to customize the material properties ensures that products can withstand demanding environmental conditions or mechanical stresses. As a result, plastic injection molding with additives provides an efficient way for businesses to produce robust, reliable parts that meet high-performance standards while still benefiting from the economic advantages of the molding process.

Reduced Waste and Improved Sustainability

Plastic injection molding contributes to reduced waste and improved sustainability within manufacturing processes. The precision of the molding technique ensures minimal excess material, as parts are produced with exact specifications and tight tolerances. Any leftover plastic can be collected, recycled, and reused in future production cycles, significantly reducing material waste. Moreover, the ability to use recycled plastics as raw material further enhances the environmental efficiency of this method. By opting for eco-friendly additives and materials designed to biodegrade or have a smaller ecological footprint, businesses can align with sustainable practices and reduce their overall environmental impact.

Plastic injection molding stands out as a pivotal manufacturing process that offers myriad advantages for businesses across various industries. From the significant cost savings in large-volume production to unparalleled precision and consistency, this technique is well-suited for companies aiming to innovate while maintaining high standards. The versatility in material and color choices, combined with efficient production speed and output, enables businesses to meet specific needs and respond swiftly to market demands. The enhanced strength through additives and the process’s commitment to sustainability underscores its value as a forward-thinking solution.