Element materials technology is at the forefront of innovation, driving advancements in various industries. From aerospace to electronics, these materials play a crucial role in shaping the future of technology. With their unique properties and applications, element materials are revolutionizing the way we approach design and manufacturing.

In this article, we delve into the world of element materials technology, exploring the latest trends, applications, and breakthroughs in the field. Discover how these materials are reshaping the landscape of modern technology and pushing the boundaries of what is possible. Stay tuned to learn how element materials are paving the way for a new era of innovation and sustainability in the tech industry.

In this article, we delve into the world of element materials technology, exploring the latest trends, applications, and breakthroughs in the field. Discover how these materials are reshaping the landscape of modern technology and pushing the boundaries of what is possible. Stay tuned to learn how element materials are paving the way for a new era of innovation and sustainability in the tech industry.

Element materials technology plays a pivotal role in driving innovation across various industries, including aerospace and electronics. These materials offer unique properties that are essential for shaping the future of technology. The latest trends, applications, and breakthroughs in element materials technology are revolutionizing design and manufacturing processes, pushing the boundaries of what is achievable in the tech industry.

Element Materials Technology

Industries across the globe heavily rely on element materials due to their unique properties and versatile applications in modern technologies.

- Enhanced Performance: Element materials, such as carbon fiber and titanium, offer superior strength-to-weight ratios, enhancing the performance of various products in industries like aerospace, automotive, and sports equipment.

- Durability and Reliability: The exceptional durability and corrosion resistance of element materials like stainless steel and aluminum make them ideal for demanding applications in construction, marine, and chemical industries.

Efficiency and Sustainability: Element materials play a vital role in improving energy efficiency and promoting sustainability. For instance, the use of advanced composites in wind turbine blades enhances energy generation while reducing environmental impact.

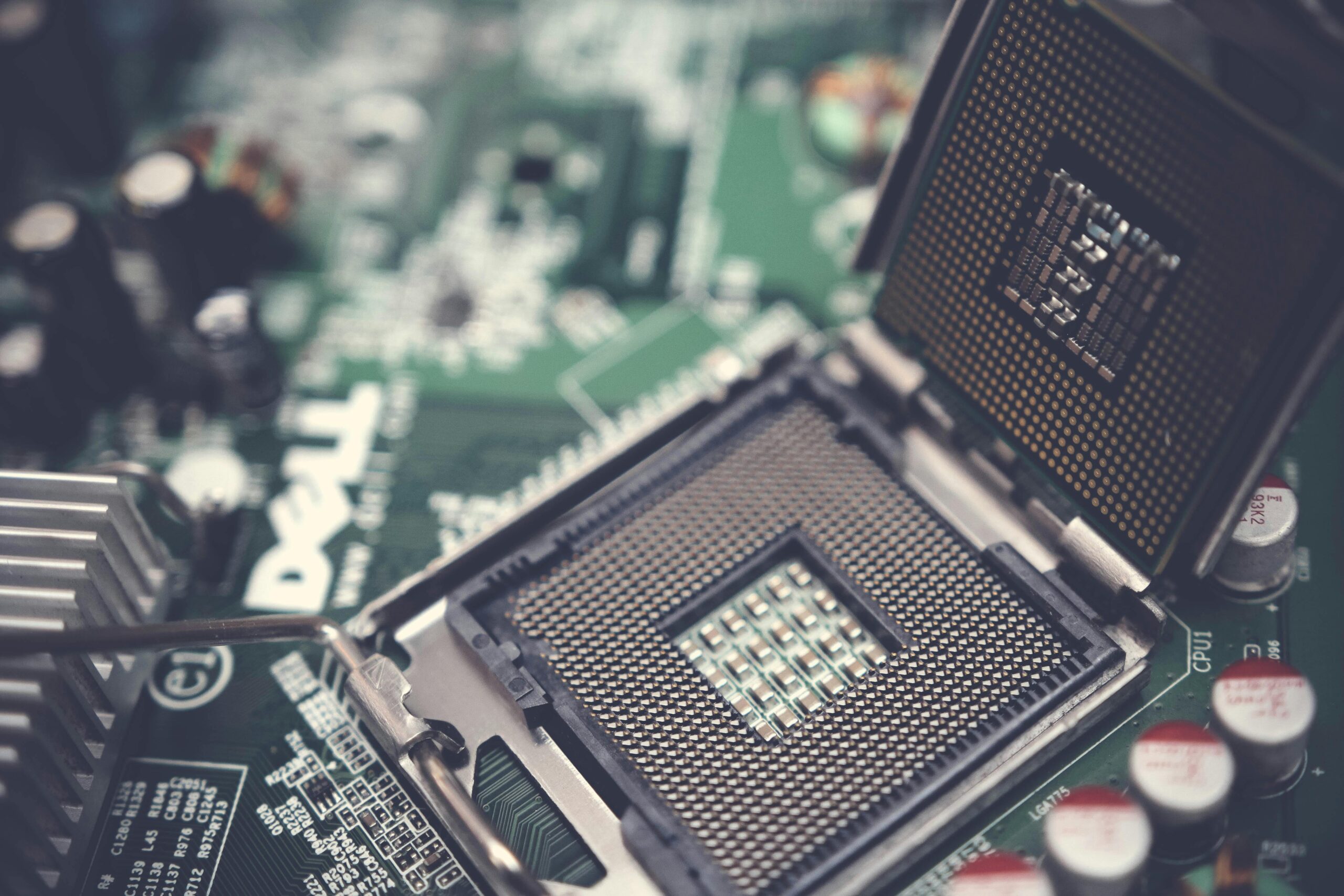

Efficiency and Sustainability: Element materials play a vital role in improving energy efficiency and promoting sustainability. For instance, the use of advanced composites in wind turbine blades enhances energy generation while reducing environmental impact.- Miniaturization and Innovation: In electronics, the miniaturization of components using materials like silicon and gallium arsenide has revolutionized the industry, enabling the development of compact devices with enhanced performance.

- Future Prospects: The ongoing research and development in element materials, such as nanomaterials and metamaterials, hold immense promise for future technologies like quantum computing, advanced sensors, and advanced propulsion systems.

- Global Impact: Element materials technology has a significant global impact, driving innovation, shaping industries, and fostering economic growth by pushing the boundaries of what is achievable in modern manufacturing and design processes.

By harnessing the unique properties and capabilities of element materials, industries can continue to push the limits of innovation and unlock new possibilities for the future of technology.

Advancements in Element Materials Research

Exploring cutting-edge advancements in element materials research unveils a realm of possibilities for revolutionizing various industries. Researchers continuously push the boundaries of science and technology to discover new applications and enhance existing materials’ properties.

- Innovative Nanomaterials: Scientists are delving into the realm of nanomaterials, manipulating elements at the nanoscale to create novel materials with unique characteristics and performance benefits.

- Metamaterials Development: The development of metamaterials, engineered to exhibit properties not found in nature, opens up avenues for unprecedented applications in fields like optics, acoustics, and electromagnetics.

Exploration of Quantum Materials: Researchers are venturing into the realm of quantum materials, harnessing quantum mechanics to create materials with exceptional electronic, magnetic, and thermal properties.

Exploration of Quantum Materials: Researchers are venturing into the realm of quantum materials, harnessing quantum mechanics to create materials with exceptional electronic, magnetic, and thermal properties.- Emergence of 2D Materials: The emergence of two-dimensional materials like graphene has sparked interest due to their remarkable strength, flexibility, and conductivity, paving the way for revolutionary advancements in various industries.

- Advancements in Material Characterization: Innovations in material characterization techniques, such as high-resolution imaging and spectroscopy, enable researchers to delve deeper into understanding the intricacies of element materials’ structures and behaviors.

- Integration of Artificial Intelligence: The integration of artificial intelligence in material design accelerates the discovery of new materials by predicting their properties, leading to faster innovation and optimization processes.

Challenges and Limitations in Element Materials Development

In the realm of element materials development, researchers and industries encounter various challenges and limitations that shape the advancement of this field. These obstacles play a crucial role in determining the feasibility and practicality of integrating new element materials into existing technologies and applications. Some of the primary challenges and limitations in element materials development include:

- High Manufacturing Costs: The production of certain element materials can be prohibitively expensive, impacting their widespread adoption in various industries. This cost factor poses a significant barrier to scaling up the usage of advanced materials in manufacturing processes.

- Limited Availability of Raw Materials: Some element materials rely on scarce or limited natural resources for their production. This scarcity can lead to supply chain disruptions, affecting the consistent availability of these materials for industrial applications.

Complex Processing Techniques: The fabrication and processing of certain element materials require sophisticated techniques and equipment. This complexity adds to the overall production costs and can hinder the seamless integration of these materials into commercial products.

Complex Processing Techniques: The fabrication and processing of certain element materials require sophisticated techniques and equipment. This complexity adds to the overall production costs and can hinder the seamless integration of these materials into commercial products.- Durability and Reliability Concerns: Ensuring the long-term durability and reliability of element materials in real-world applications is a critical challenge. Factors such as material degradation, environmental influences, and performance under varying conditions need to be thoroughly evaluated to guarantee the integrity of the final products.

- Regulatory Hurdles: Compliance with industry regulations and standards presents another obstacle in the development and deployment of element materials. Meeting stringent regulatory requirements while maintaining performance and cost-effectiveness can pose significant challenges for manufacturers and researchers.

- Integration with Existing Systems: Incorporating new element materials into existing systems and technologies requires seamless compatibility and integration. Adapting these materials to work efficiently with established processes and components can be a complex undertaking that necessitates careful planning and testing.

Element Materials Technology – Cornerstone of Innovation

Element materials technology is a cornerstone of innovation in key industries like aerospace and electronics. From carbon fiber to titanium, these materials elevate performance standards. Silicon’s role in electronics miniaturization and the rise of nanomaterials further exemplify the potential for advancement.

Element materials technology is a cornerstone of innovation in key industries like aerospace and electronics. From carbon fiber to titanium, these materials elevate performance standards. Silicon’s role in electronics miniaturization and the rise of nanomaterials further exemplify the potential for advancement.

Despite challenges like high costs and regulatory barriers, overcoming these hurdles is essential for unleashing the full power of element materials. By addressing manufacturing complexities and ensuring sustainable sourcing, industries can harness the transformative capabilities of these materials.